Cart

You have no items in your shopping cart

|

|

| Software MEGACAD 2D/3D | Software SolidWorks 3D |

|

|

| Software CIMATRON 3D | Software CIMATRON 3D NC - programming |

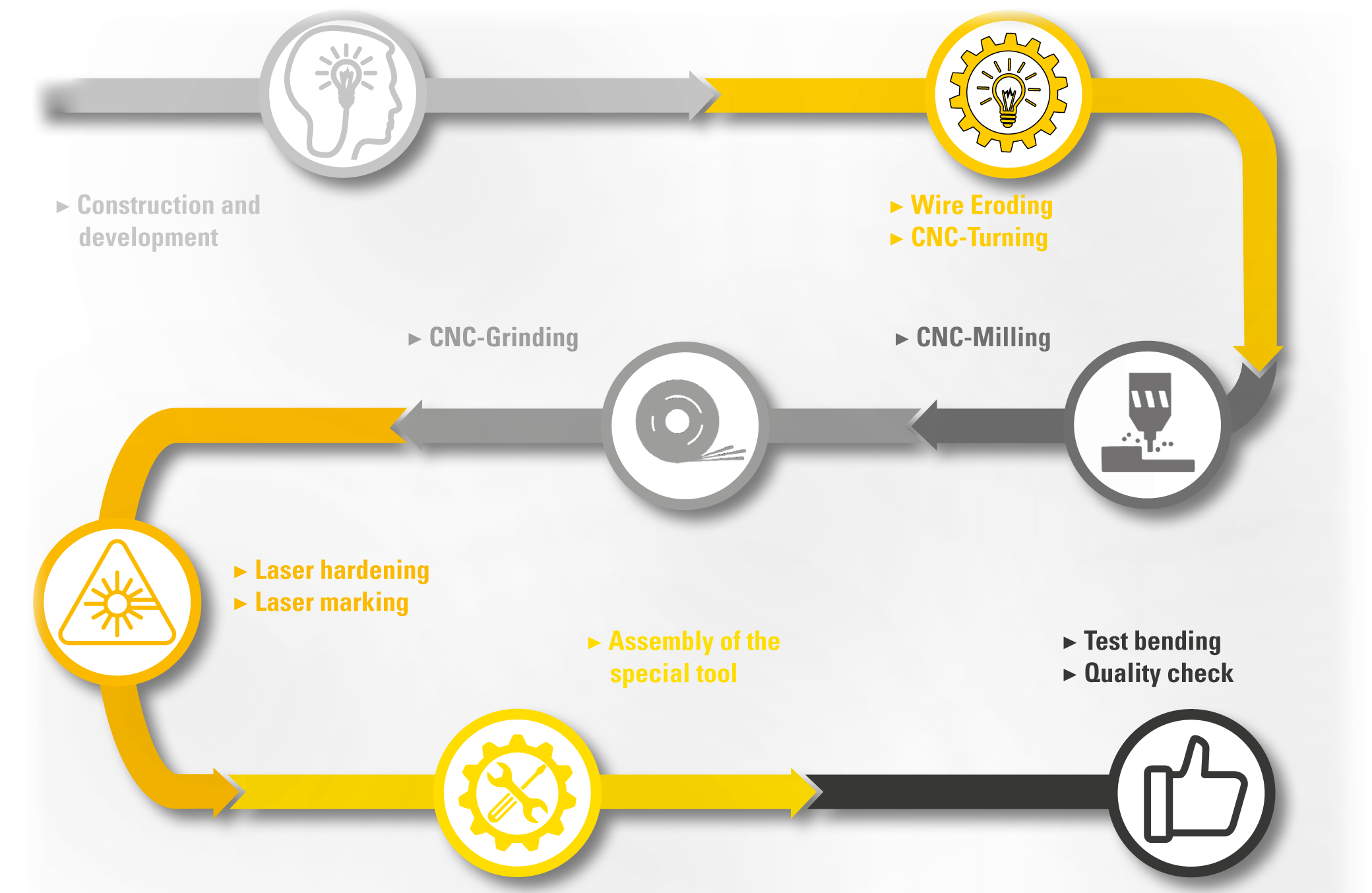

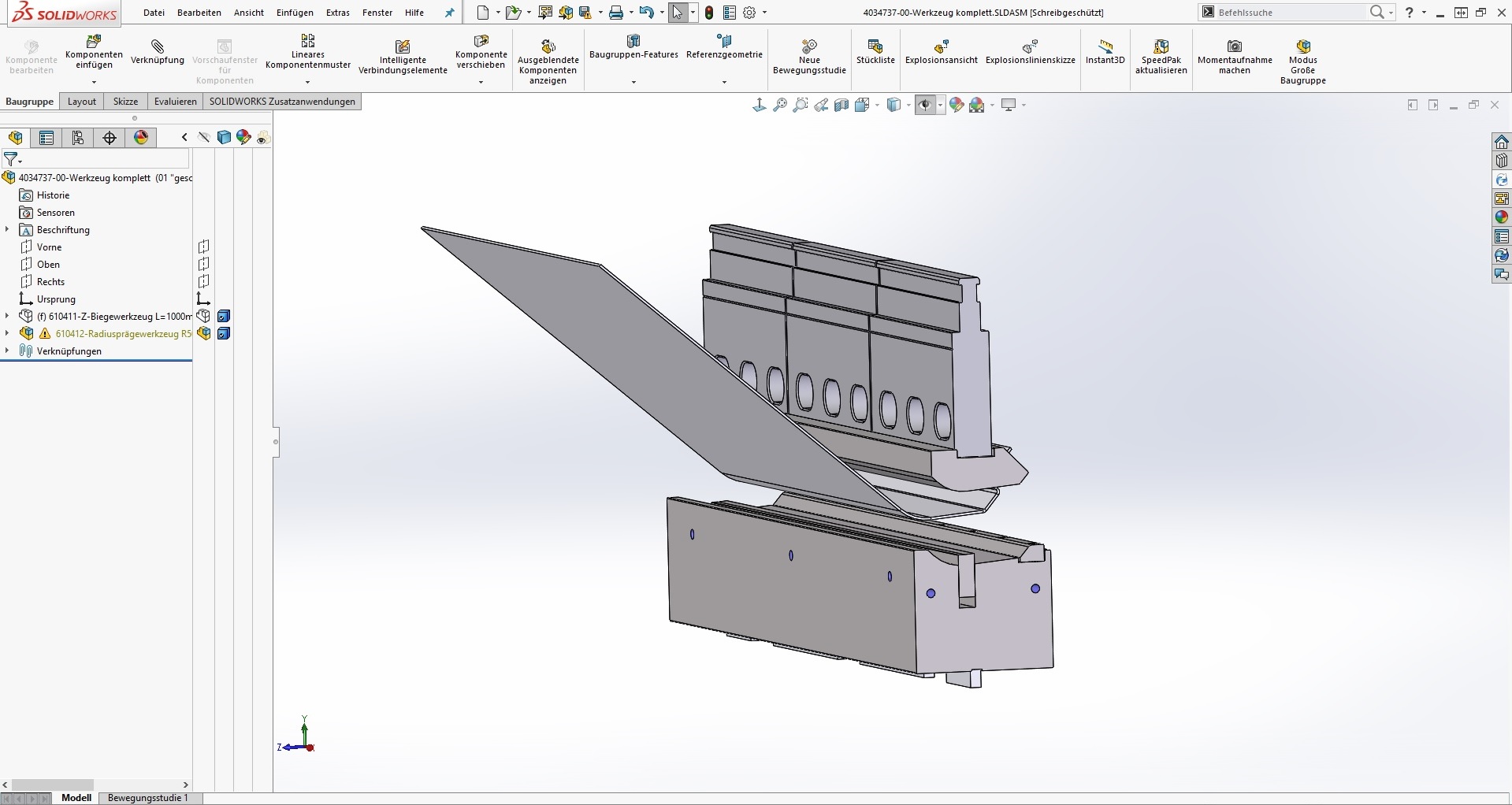

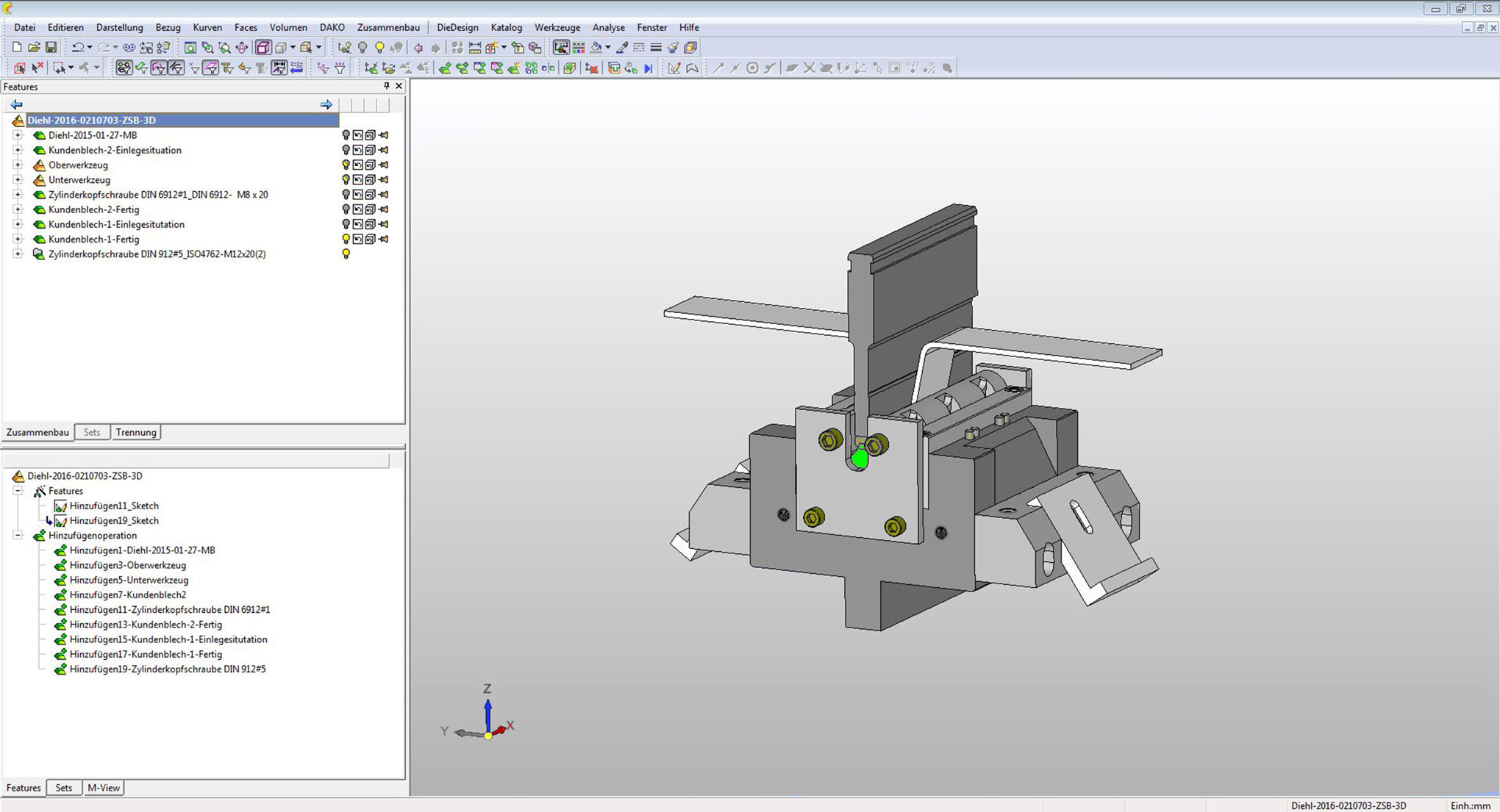

| After receiving the order the offered concept will be specified and will be presented to you by a drawing for acceptance/model. After the approval we prepare the production plans and drawings. | |

|

TECHNICAL INFORMATION:

|

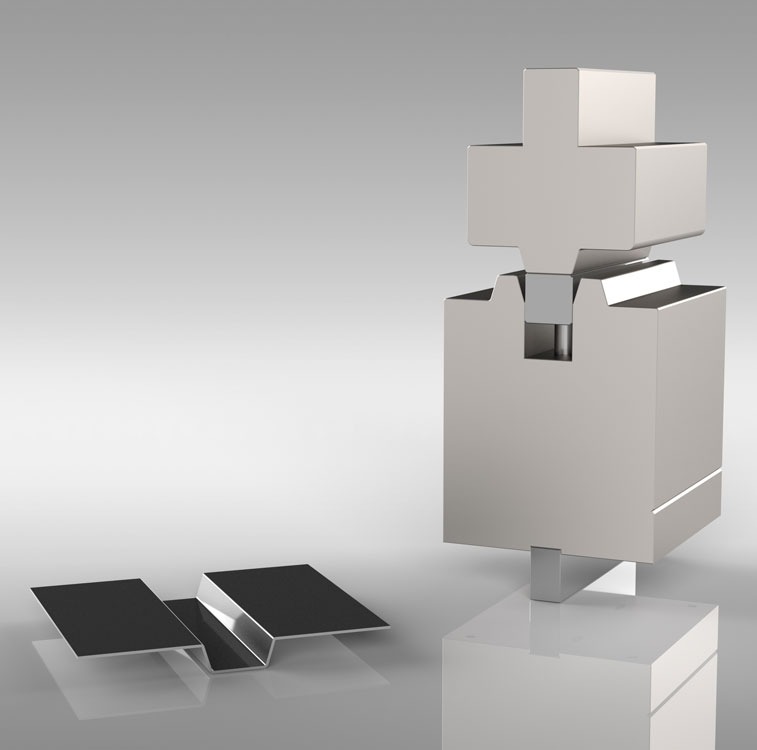

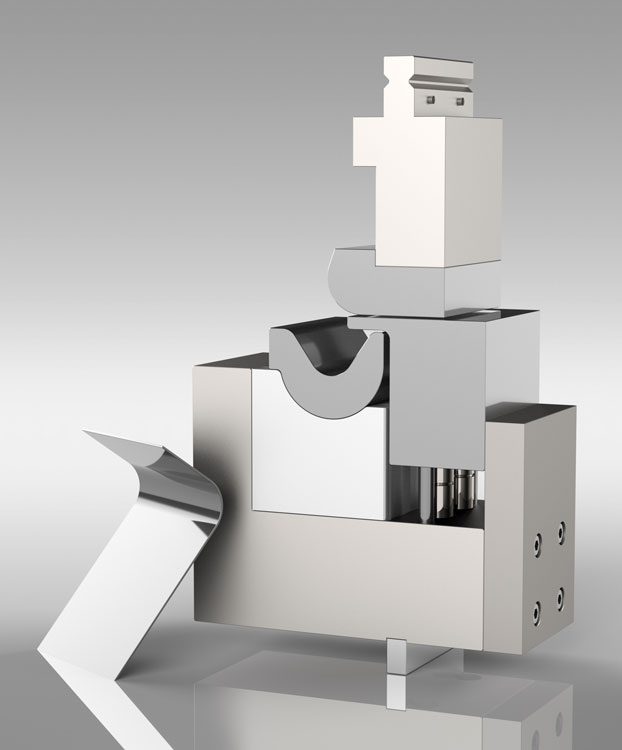

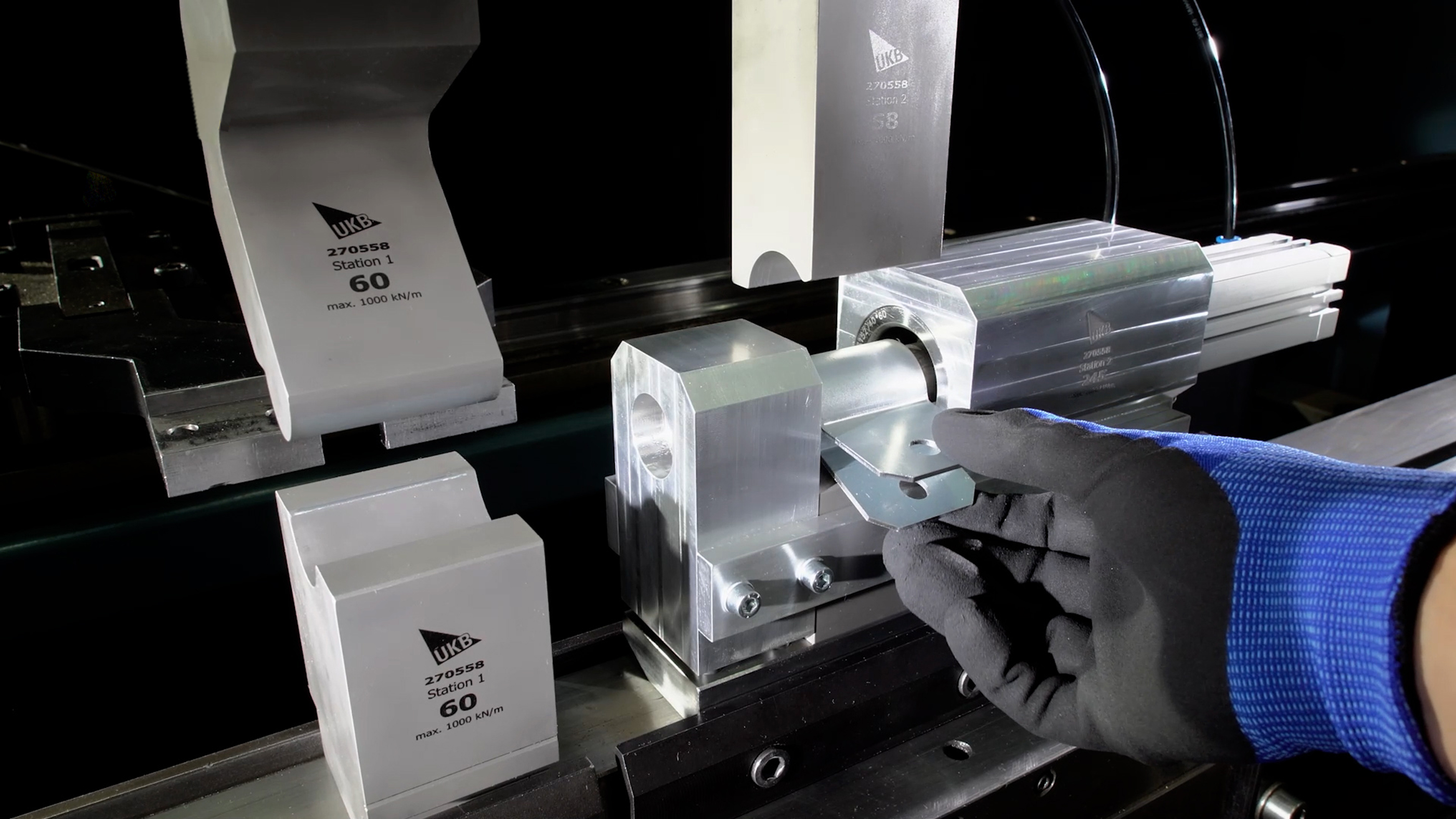

| To determine the optimum bending contour, a sample tool will be produced. After sampling took place this contour will be transmitted to the serial tool. | |

|

|

|

TECHNICAL INFORMATION:

|

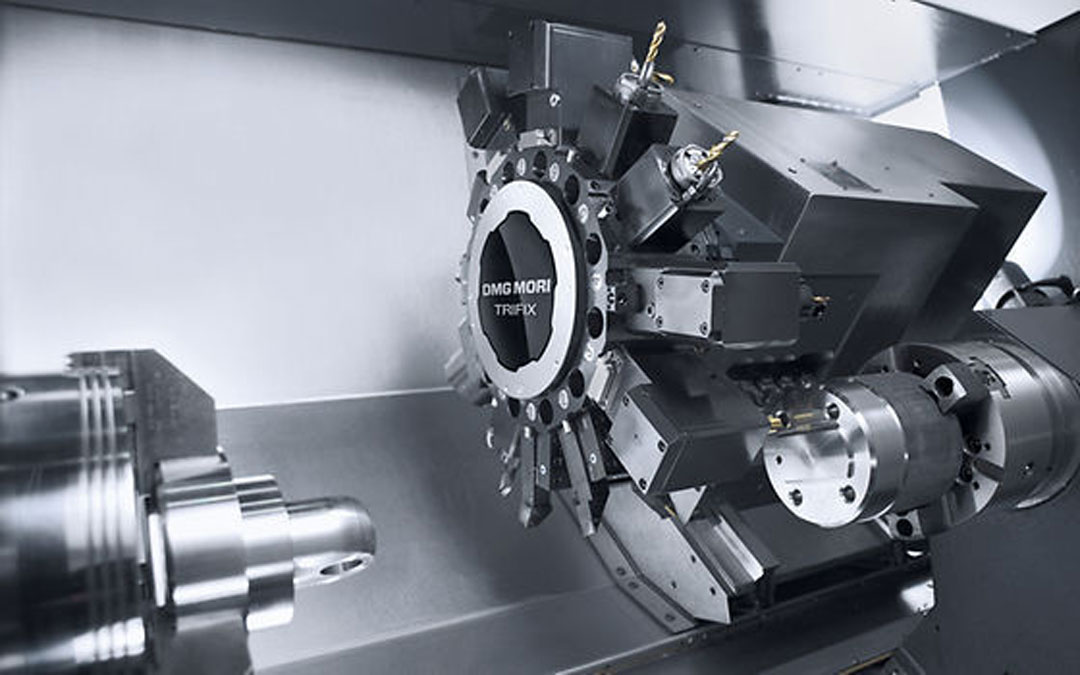

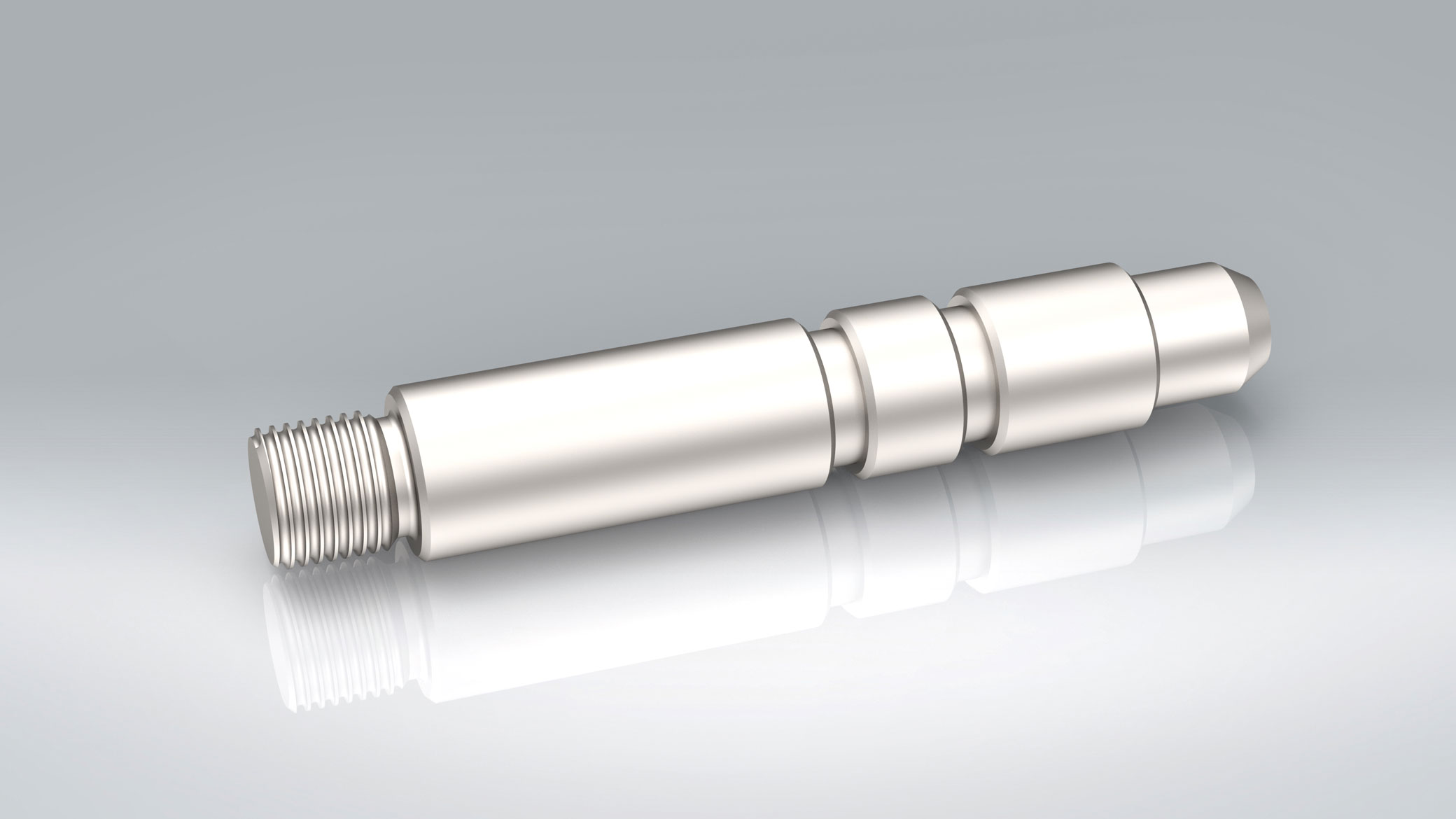

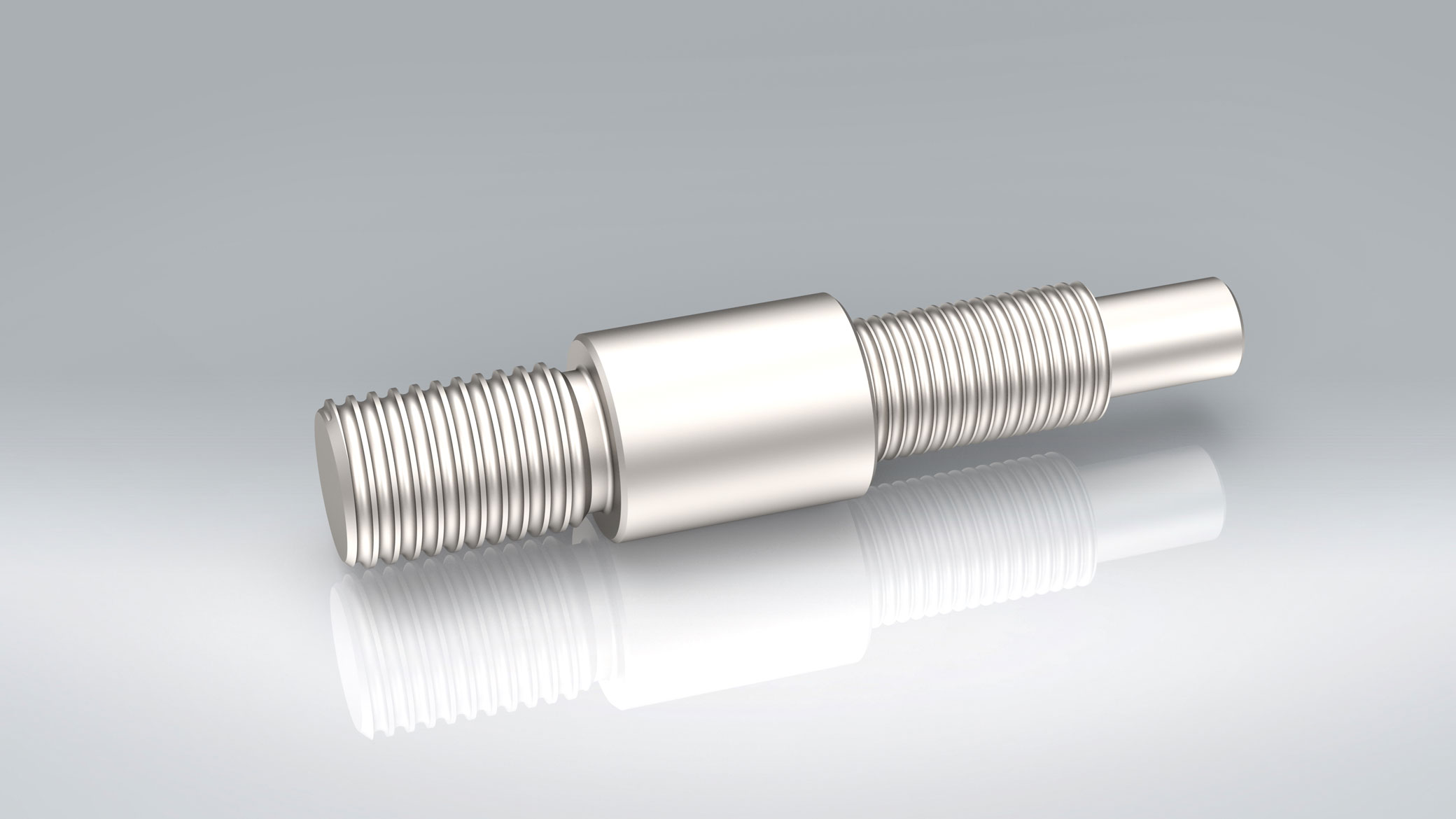

| Due to a 6-sided complete machining with counter spindle and Y-axis, the CNC-turning can be precisely performed according to the specific requirements. | |

|

|||

|

|||

|

|

TECHNICAL INFORMATION:

|

||

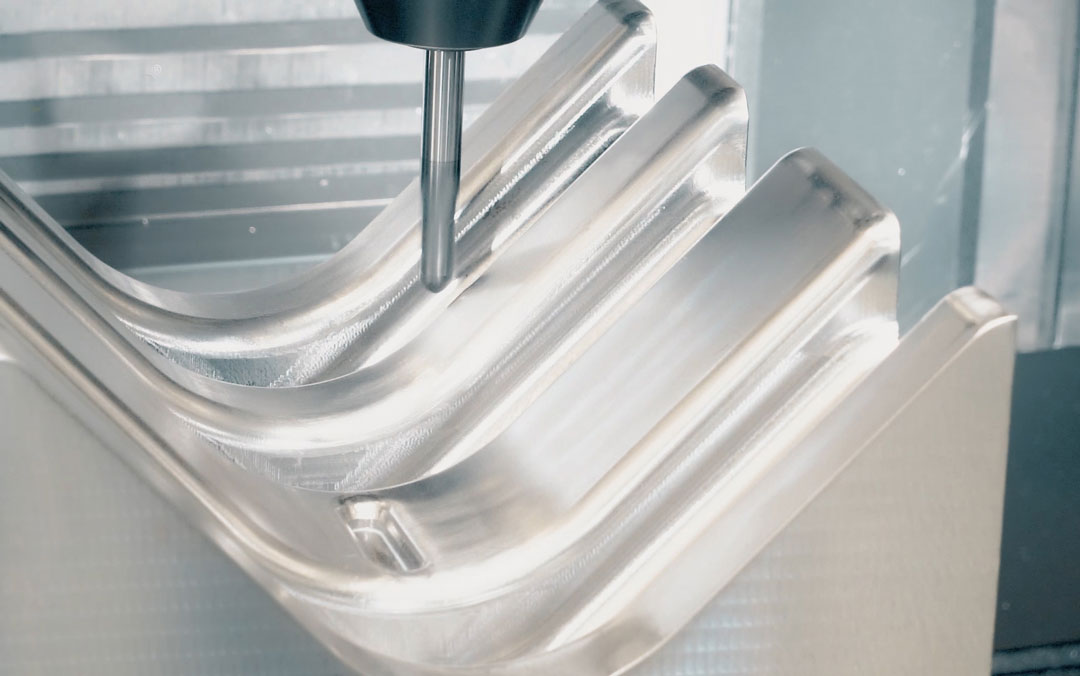

| The components are machined according to the production drawing on our CNC-milling machines. Using 5-axis processing even complex tool contours can be produced. With the latest machines to the best results! |

|||

|

|||

|

|||

|

|

TECHNICAL INFORMATION:

|

||

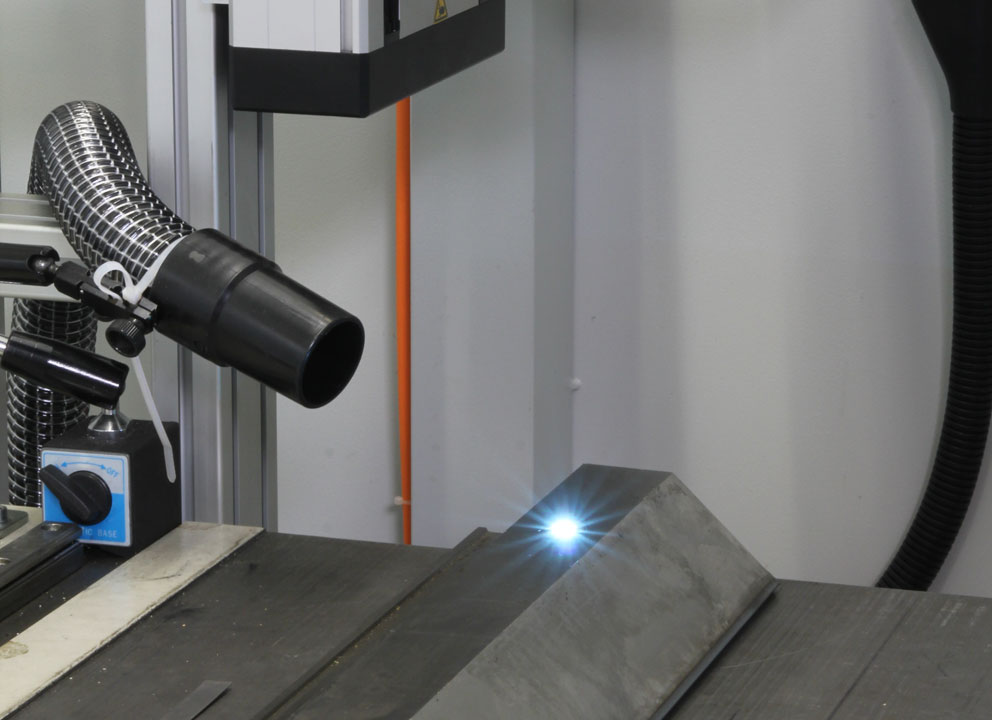

| The bending contour and the active surfaces of the special tool will be precision ground. For precise tasks we are perfectly equipped! | |||

|

|

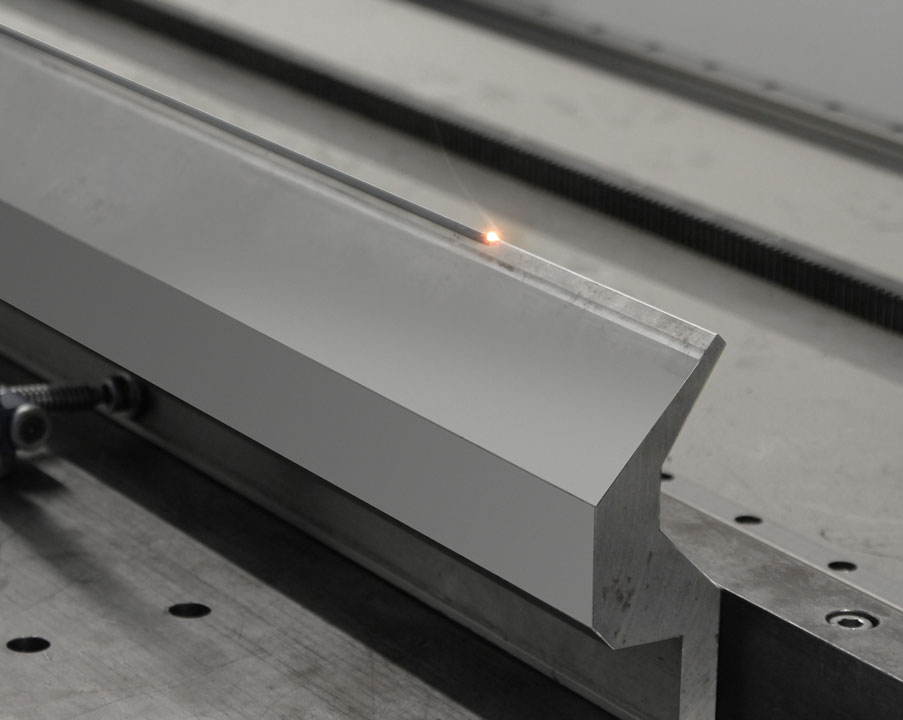

| In accordance to the purpose, the tools will be laser hardened, through hardened or nitrated. | |

|

|

| Customer-specific marking such as internal tool-numbers, can be realised flexible. | |

|

|

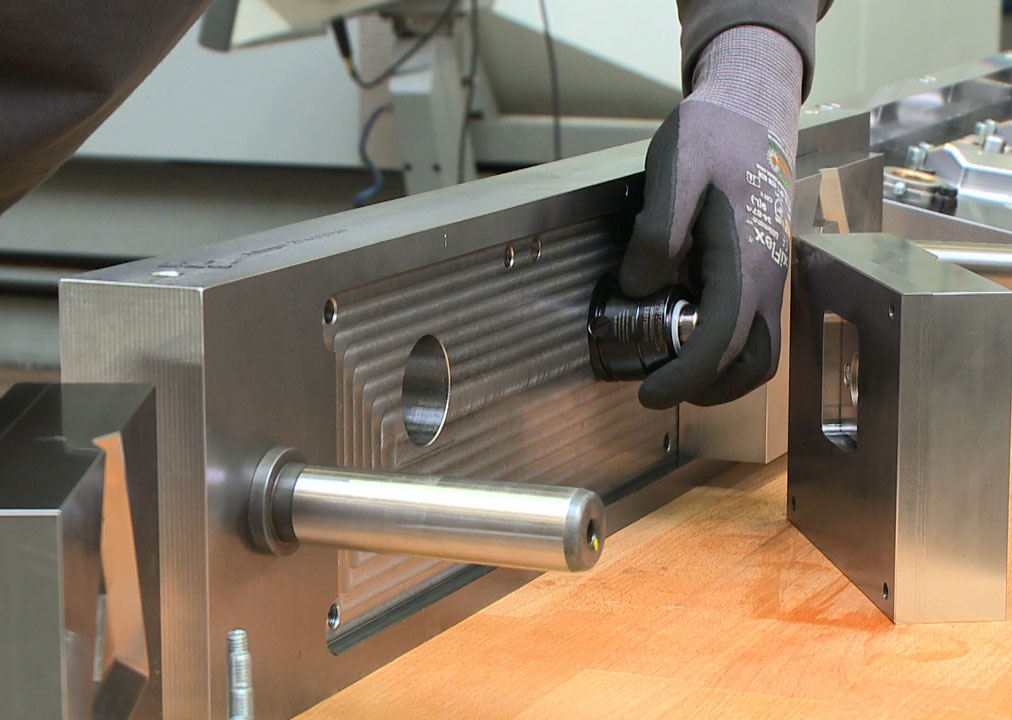

| The single componets will be assembled and aligned to each other. | |

|

|

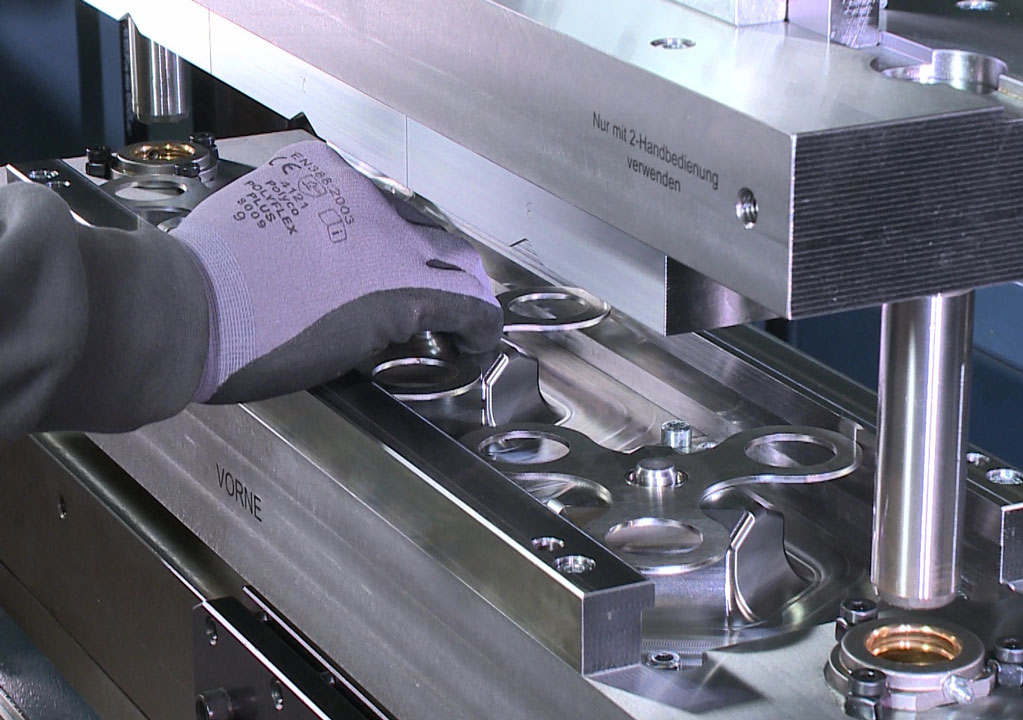

| Finally the functional test will be done with your sample sheets. Test bendings will be performed on our press brake (L = 4050 mm, press force 3200 kN) at the UKB-test center. |

|

|

|

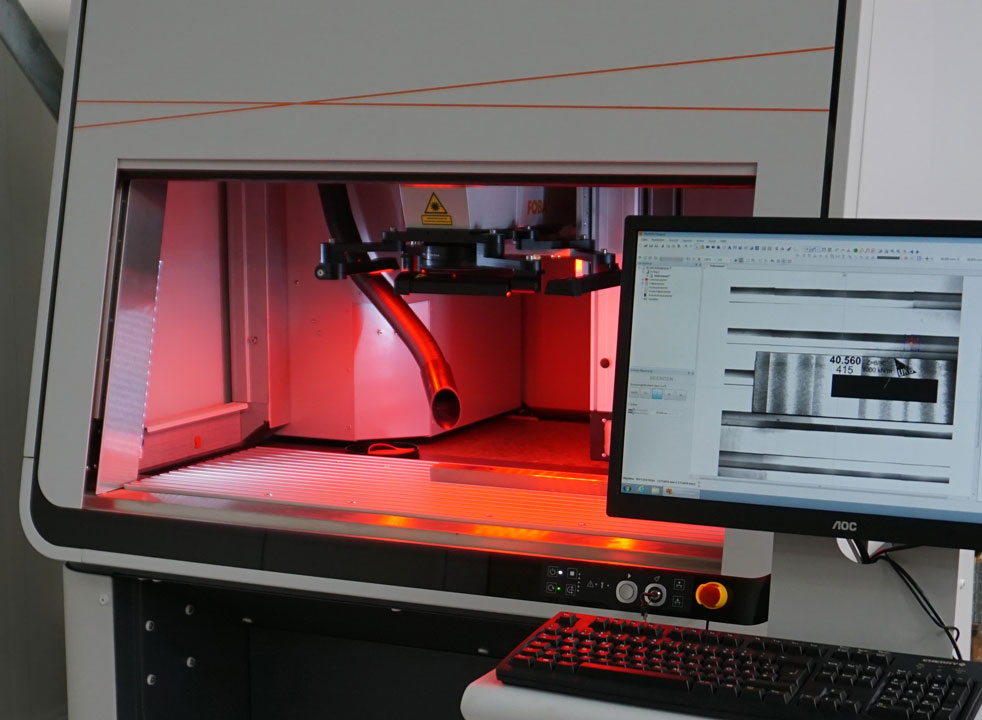

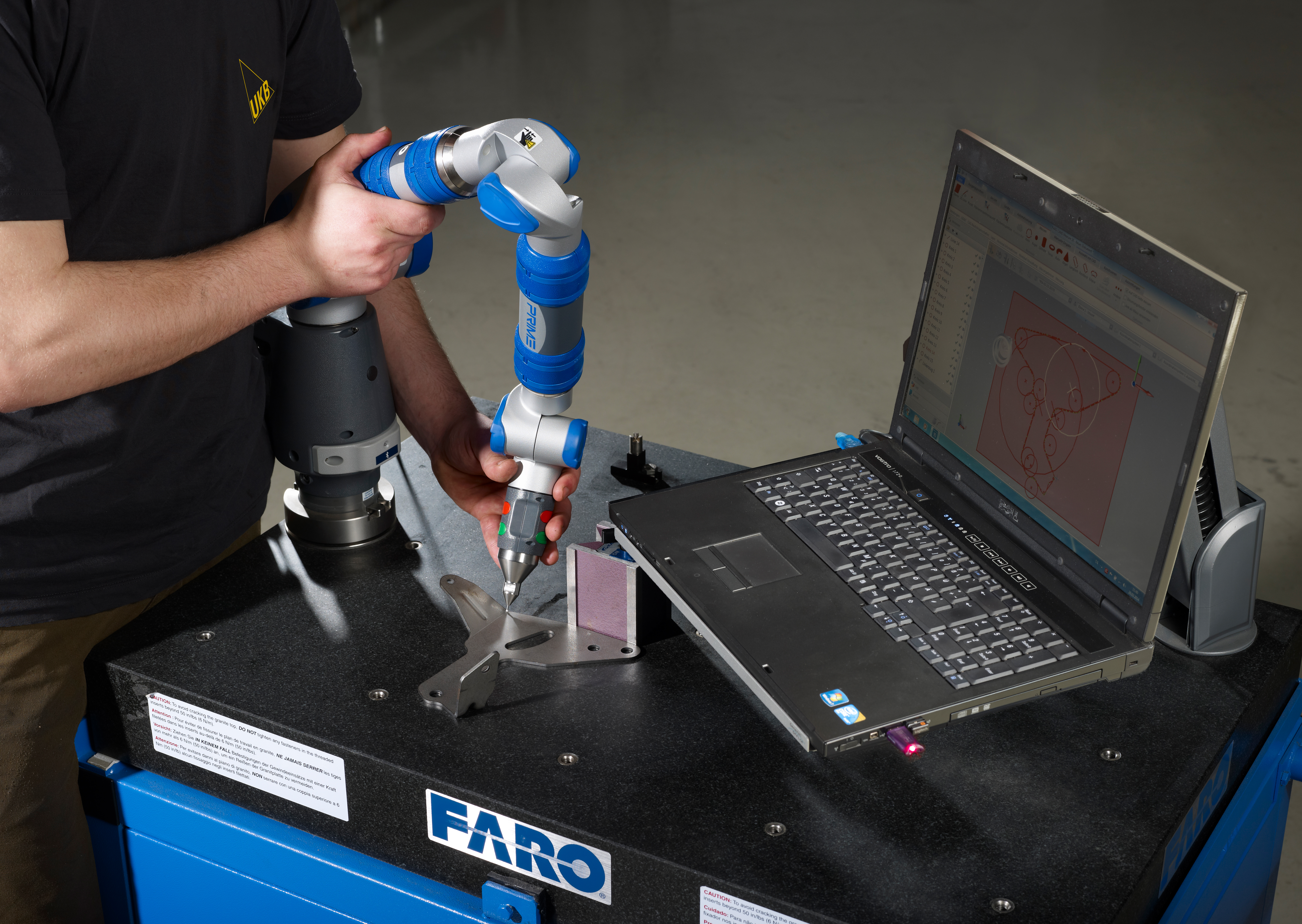

| The complete production process is accompanied by continuous quality controls, such as 3D-measuring and hardening tests. | |